-

August 28, 2025

- Posted by: sitemadmin

THE DIFFERENT TYPES OF PIPE AND FITTINGS: WHAT THEY ARE FOR AND THE BENEFITS OF USING THEM

I. Introduction to types of Pipe and Fittings

A. Definition and Purpose

The unsung heroes of any building’s infrastructure are the pipes and fittings. Pipes direct fluids – such as water, gas and oil — through residential homes and commercial buildings, which means fittings are an essential part of connecting these pipes together for straight or turns in the required direction. We would all be pickled by the time we turn on our taps.” Without them, life and plumbing wouldn’t work at all. Just think about getting cleaned up in a shower with no hot water running through the pipes, or heating system at your home without proper connections!

Those both components are crucial for home use, and the same is true with businesses,” Olmsted said of proper plumbing — to say nothing of other systems they power or enable everything from sanitation to heating.

B. Significance in Different Industries

The significance of pipes and fittings extend to households, Construction Industry along with different types of Industries. Come, let us know

- Plumbing and Sanitation: In plumbing and sanitation, the pipe and fittings help to flow the water safely and remove the waste effectively.

- HVAC and Refrigeration: Pipes also used in HVAC and Refrigerators to pass the cooling fluids which are essential for comfortable living and working environments.

- Industrial Applications : In manufacturing Industries, Pipes are used to move the chemicals and other materials safely.

C. Manufacturing and Material Considerations

Various factors need to be considered while manufacturing Pipes and it’s a very complex task.

- Types of Manufacturing Processes: Mostly there are two types of extrusion (for plastics) and welding(for metals), but here are some other processes inside this operation.

- Selection of Materials: Suitable material for the pipes have been selected on the basis of type of fluid handled, temperature and pressure to be withstood by it.

- Standards and Certifications: It’s very important for your pipes and fittings to be in compliance with the industry standards as this assures you of their safety, reliability.

II. Types of Pipes

A. Metal Pipes

Metal pipes have been a reliable choice for many years:

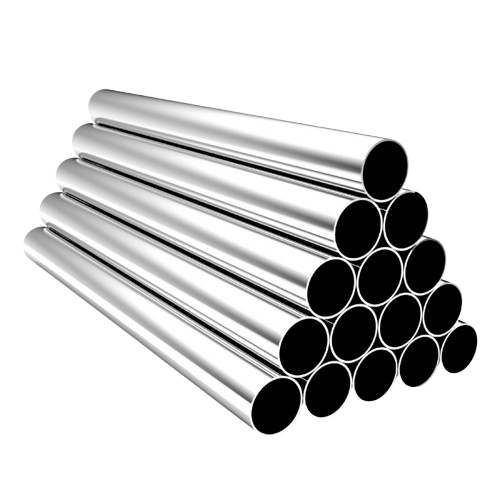

- Steel Pipes: If you are interested in heavy equipment, steel pipes may be what interests your investments since they have the strength to last through construction work and also oil or gas activities.

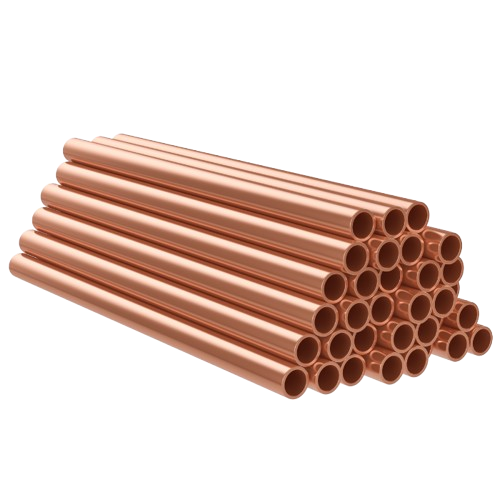

- Copper Pipes: Generally preferred in plumbing systems, copper pipes have relatively high corrosion resistance, and good heat conductivity – perfect for hot water applications.

- Cast Iron Pipes: Known for being resistant and long lasting, these pipes are found in older homes as well as ones with drainage systems.

B. Plastic Pipes

Recently, pipes of plastic have become popular:

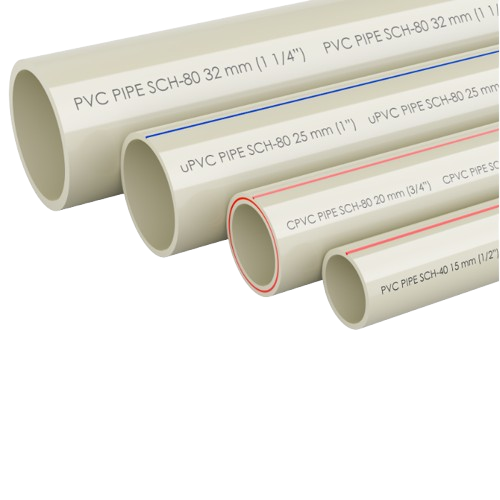

- PVC Pipes: PVC pipes are light weight and resistant to corrosion which makes them widely used for plumbing, drainage. They’re easy to set up, too!

- CPVC Pipes: Having a temperature rate that is above PVC, the CPVC makes an ideal option in applications of hot water. They also resist chemical damage.

- PEX Pipes: PEX pipes can bend and shape to fit a plumbing setup of any size, which is perfect for retrofitting needs.

C. Other Pipe Materials

Although metal and plastic are the two most common materials people gravitate toward, there are other options as well:

- HDPE Pipes: Virtually indestructible, high-density polyethylene pipes perfectly suited to drainage and irrigation projects in extreme conditions.

- Concrete Pipes: Concrete pipes are used for internal transportation of large quantities of water, in civil engineering projects and treatment to wastewater.

- Fiberglass: These pipes perform well in areas of corrosiveness and are typically used for their strength and resistance.

III.Different types of Pipe Fittings and their functions

A. Commonly Used Fittings

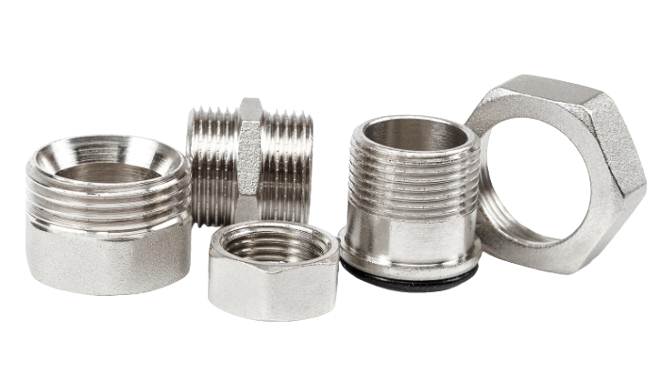

Fittings are used to extend or change the course of a pipe:

- Elbows: Used to shape pipe in a direction; either long or short radius.

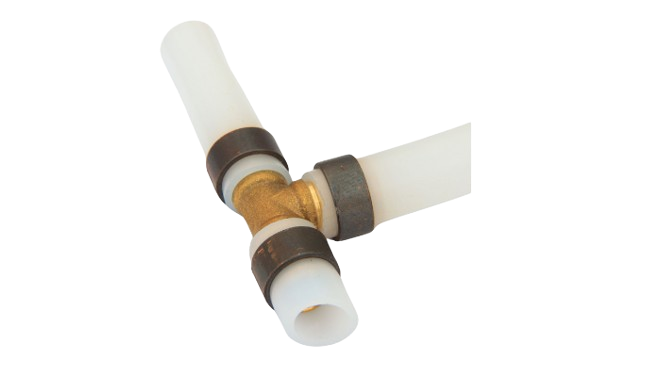

- Tees: Used to add runners, tees can be used for extending plumbing lines.

- Couplings and Adapters: These fittings are used to join two or more pipes of the same size, thereby creating a tight joint.

B. Specialty Fittings

Some fittings have specialized functions:

- Unions – These allow for highly simple disconnects when there is need to carry out maintenance or repair.

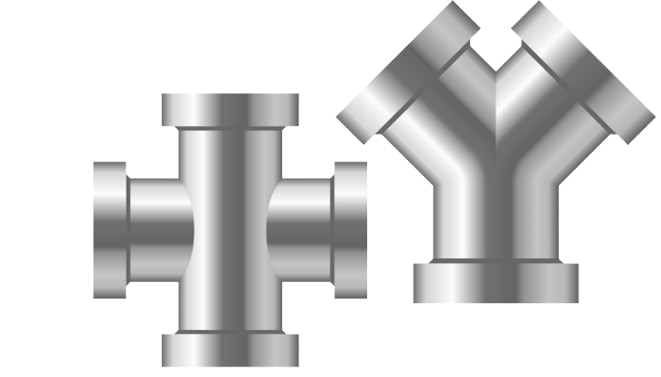

- Cross Fittings: Offered to us for multi-way flow, this item is a cross which enables one branch in four directions.

- Reducers: Converters that change the size of a pipe to meet different flow specifications.

C. Material-Specific Fittings

Fittings come in a range of materials, each being tailored to specific applications:

- Metal Fittings: Good for high pressure but, need to be long lasting for.

- Plastic Fittings: These are ideal for use in low-pressure lightweight corrosion resistant systems.

- Composite Fittings: Taking a little from one and the best of both worlds.”composite fittings are designed on mixed lines!

IV. Choosing the Right types of Pipe and Fittings

A. Factors to Consider

There are some factors to be considered while selecting the pipes and fittings.

- Pressure Ratings and Temperature Limits: we need to check that the pipe system can be able to handle the fluids and pressures expected which are going to pass through the channels.

- Compatibility: It should be clear that the material should not interact with the fluids.

- Environmental Conditions: The durability should be very good even if it is exposed to local environmental factors and any applicable regulations.

B. Installation Considerations

We have to pay the attention carefully while installing pipes and fittings:

- Tools and Techniques: The tools which are used are different from material to material. Before installing, we must know which tool should be used for our particular material.

- Special Considerations: In underground Installation, we have to check twice or thrice whether the pipes are correctly buried and secured to prevent future problems.

- Following the Safety Measures: We are always recommended to follow the safety guidelines as it will help you in getting a safe and sound installation work process.

C. Maintenance and Longevity

In order to keep our piping system in a good condition, it is compulsory to do the maintenance of it.

- Regular Inspection: Before it goes out of our hands i.e., before it could be more damaged we should have an eye on whether that’ll work or not. So if we see signs of any minor damage then they could be easily recovered.

- Cleaning Methods: Cleaning methods are the same for all materials. Hence we should have knowledge about which type of material we are using and how well maintained it is.

- Expected Life: It is necessary to know when the specific parts should be replaced and kept from any future failures.

V. Innovations in Pipe and Fittings Technology

A. Advances in Materials

In future, though things could go much better:

- Corrosion Mitigation Technologies: Novel pipe coatings are under development to increase the life of a pipeline.

- Flexible Piping Systems: These are designed for easy installation in restricted or awkward places.

- Smart Pipes: Some companies are adding sensors to pipes that detect leaks in real time.

B. Sustainability and Eco-Friendly Options

The industry is being driven by rising environmental consciousness:

- Biodegradable Pipes and Fittings: Recent entrants to the field are materials that ultimately will disintegrate over time.

- Recyclable: It is useful to recycle pipes as it prevents waste and promotes environmental friendly practices.

- Energy-Conserving Installations: Distinct technological novelties that may improve energy conservation of piping systems are gathering momentum.

C. Future Directions of the Industry

The rise of urbanization, the industry will have to change:

- Automation and Robotics:This is the 1st time ever dared a Global Pandemic World to move towards Automation and Robotics – Installations, Maintenance will be relied heavily upon Technology.

- Challenges of Modern City: Updated designs are emerging to meet the needs of larger urban areas.

- Next-Gen Materials: The future could hold materials that would make us scratch our heads today.

VI. Conclusion

This blog discusses the different types of pipes and fittings present in the market, their significance and predominant role in different sectors. And what are the most influential factors to consider when selecting the components so that to make the decision wisely and the components would perform well for years. Whether you are designing a large-scale industrial project, do not forget to consider all your options and make a wise selection!

Need some high quality hydraulic hoses and hose fittings for your next project?